Electrical Safety Grounding Explained

By EF

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Electrical safety grounding establishes earthing and bonding paths, controls fault current, stabilizes voltage, and protects equipment via ground electrodes, equipotential bonding, surge protection, and NEC/IEEE-compliant grounding conductors, reducing touch voltage and arc flash risk.

What Is Electrical Safety Grounding?

Earthing and bonding system directing fault current to ground, limiting touch voltage and protecting equipment per code.

✅ Provides low-impedance fault current paths to trip protection

✅ Maintains equipotential bonding to reduce touch voltage

✅ Complies with NEC/IEEE grounding and bonding standards

Electrical safety grounding is one way used to reduce the effects of electrical hazards to persons and equipment. Electrical safety grounding works by using the earth or ground as a conductor to drain away any unwanted electrical discharges. Besides power lines and the human body (particularly the human heart), electrical current can travel through water, dirt, rocks and anything else on the ground. This fact makes the earth the ultimate conductor and a great way to promote electrical safety grounding. For foundational concepts in grounding, the overview at basic electrical safety explains how current seeks low-impedance paths in ways relevant to soil conditions and electrode design.

In practice, if any electrical wiring becomes faulty, then the electrical ground absorbs a large portion of the straying electrical current instead of an electrical worker repairing or servicing electrical, computer or electronic systems. But, in order to achieve this, electrical circuits must be secured to the ground or the earth through a qualified electrical safety grounding system or network of systems. To reinforce these practices, consult general electrical safety guidance that outlines lockout procedures, verification steps, and protective measures for service work.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Additional risk controls are outlined in electrical safety precautions, which detail inspection routines and fault-response protocols before re-energization.

Electrical Safety Grounding -- How proper grounding improves electrical safety

Secure electrical ground connections protect workers, but also help protect the safe operation of equipment. Sometimes electrical equipment can be susceptible to electrical interference, but electrical safety grounding systems can protect against this. Also, if lightning strikes the building housing electrical equipment, a considerable amount of damage can be done, but electrical safety grounding, using the earth as a conductor, can dissipate any amount of electrical current. System components can also be damaged by electrostatic buildup, but electrical safety grounding helps to avoid damage by draining away any unwanted electrical current. A good grounded point usually has a constant voltage, no matter what happens in the system or the circuit. For broader context on control of electrical hazards, see electrical safety resources that connect grounding strategies with overcurrent protection and bonding practices.

Practical maintenance checkpoints are summarized in electrical safety tips, helping teams verify continuity, tighten terminations, and document grounding integrity during inspections.

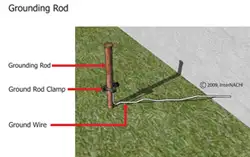

Electrical Safety Grounding – Grounding systems and circuits

A few essential pieces of equipment connect together to make a good grounded electrical safety system: the grounded conductor, the grounded bus bars, the grounded conductor for equipment, and any other metal parts that don’t possess electrical currents. This system is put together by joining an appropriately sized un-spliced grounded electrode conductor between the grounded electrode system and the grounded bus bar. Engineering-focused references like electrical engineering safety further describe sizing criteria, bonding jumpers, and fault-current pathways for compliant installations.

Integrating these design details with organizational policies from electrical health and safety strengthens worker training, incident reporting, and continuous improvement around grounding programs.